By reimagining their entire product development process, The Urban Electric Co. went from producing one to two collections a year to nearly one new product a week—a shift that led to some of the lighting firm’s most innovative fixtures yet.

For years they operated like many other manufacturers, but with Creative Director Michael Amato’s pool of inspiration—everything from Bauhaus and Josef Hoffmann to Yves Saint Laurent—the current collection cycle wasn’t working. With at most two launches per year many new designs were based on client expectations, not creative instinct. “I’ve always had designs that couldn’t get done because we didn’t have the development bandwidth,” Michael says.

From a logistical standpoint, a limited collection schedule also meant a lot of waiting. “A few of the fixtures would be ready months ahead of time, but we were forced to wait for the full collection to be ready for launch,” says Missy Hulsey, senior director of marketing. “If we were trying to get press coverage or coordinating a launch event, there were constant roadblocks and we’d end up having fixtures that were ready to launch six months prior just sitting there not doing anything.”

“We don’t let the idea of the overall collection, the idea of press, of really anything, hold us back.”

Three years ago they scrapped their collection schedule and reframed their product development process to what they call “continuous flow.” Now, as soon as a fixture is ready, it launches. “We don’t let the idea of the overall collection, the idea of press, of really anything, hold us back,” Missy says. “The number one thing our clients and designers care about is what’s new. So if we can be offering a continuous flow of new product, we always have something to talk about.”

At first the product development team didn’t have dedicated resources—including engineers or craftspeople fully focused on creating custom tooling and prototyping—but with an ambitious goal of launching one product a week, they eventually created their own team of about a dozen with the sole focus on the new.

For Michael, who recently relocated to London, the revamped process means his creativity is boundless, no longer limited solely by client desires or product category needs. He sends his sketches and concepts to the product management and design team led by Brianna Magagnoli at the Urban Electric headquarters in Charleston, South Carolina, and her team begins the process of bringing the fixture to life.

Sometimes it happens slowly, with a new fixture taking six months to be completed; other times it happens in weeks. The team meets weekly to go over what they call their “dashboard,” a pipeline of products for the next two years in all of their stages, from initial inspirations to renderings and prototypes. All the while Michael is still sketching, constantly diving into something new. “I’ve not had writer’s block yet.”

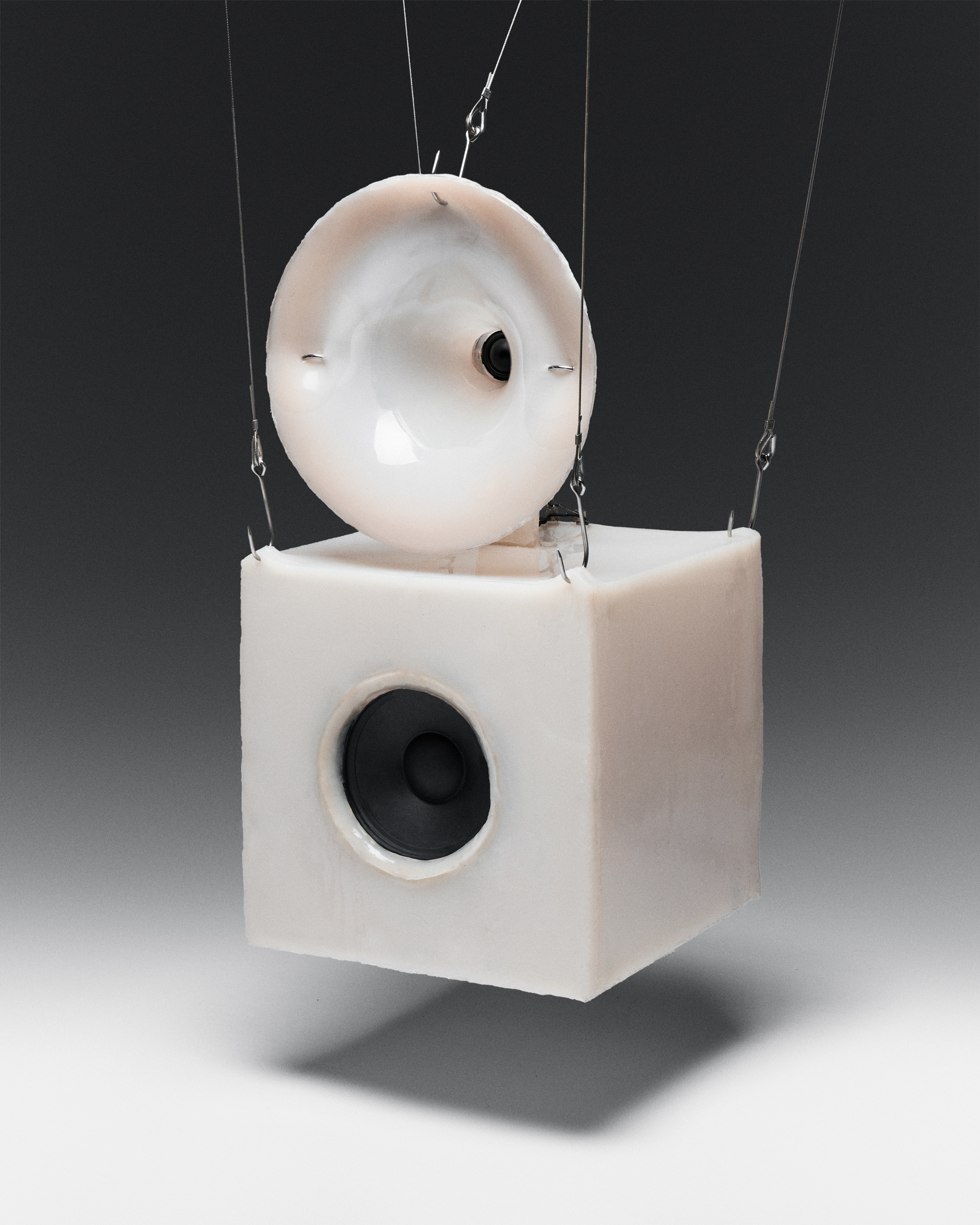

It’s been an unpredictable process—with so many products in the works, all at different stages, they never know how long each fixture will take—but five years later Urban Electric has hit its stride. After years of tinkering and refinement, 2020 has led to the one-product-per-week launch schedule the team dreamed about only a short time ago. And perhaps nothing represents their success better than Leasowe—a semi-flush, scalloped-shell pendant—which, had the idea come five years earlier, might not have been made. In fact it did, and it hadn’t.

Years ago, when Urban Electric still employed that inhibiting schedule, founder Dave Dawson took a vacation to Italy. It was supposed to be just that—a break. But when he toured a porcelain factory he was captivated by the craftsmanship. Dave brought back a small white porcelain flower and told the team about an idea he had while he was away: They had to create a fixture in porcelain.

The Urban Electric team was intrigued but wanted to learn more about the material first—its properties, what the reality of designing with it would and could look like within Urban’s overall aesthetic. So the product development team kept the idea in their back pocket, waiting for the right moment—the right fixture—to make Dave’s porcelain dream a reality.

Fast-forward to 2020 when Urban Electric collaborated with designer Martin Brudnizki. “Martin wanted another material—plaster, alabaster, something else,” Missy says. “We thought, ‘Maybe this would be a great one for porcelain.’”

So they experimented and tested its limits to see how it might work. They traveled to Italy to see the porcelain house Mangani. And of all the research, fiddling, and fine-tuning—changes not unlike the refinements made to their creative process—came Leasowe. The finished fixture has two versions—one metal and one, finally, porcelain.

While just one fixture in a stream of many, Leasowe showcases the creative freedom Michael and the team didn’t have before. By opening up their schedules, they’ve unlocked new design possibilities. “Our process isn’t confined,” Michael says. “For us the options are limitless now.”

A version of this article originally appeared in Sixtysix Issue 05 with the headline “Making the Leasowe Pendant.” Subscribe today.