When I talk with Brandon Jorgensen, senior designer for the Portland-based lighting and hardware brand Rejuvenation, he speaks slowly, choosing each word deliberately. I can tell he’s thoughtful, patient, that he’s the type of person who considers each decision carefully. His attention to detail is clear, whether he’s talking about lighting design or fly-fishing.

Brandon has long been aware of Rejuvenation; he’s worked 14-plus years in lighting in the region and was born and raised in Portland, Oregon. He’s been keeping an eye on what the Pacific Northwest-based company was up to for as long as he can remember. Rejuvenation has been designing, restoring, and assembling lights in Portland for more than 40 years. The company started as a salvage brand in 1977, restoring antique lighting before moving into reproducing period-authentic fixtures. The lighting and hardware brand has grown to 10 stores across the US. Historically most light fixtures were cast in solid brass, and Rejuvenation carries on that tradition. The company is known for its designs in various aesthetics (all customizable)—including having clean and simple lines on organic forms, offering an elegant take on industrial lighting and hardware, and putting a modern spin on traditional lighting with authentic details and classic silhouettes from every era.

“Rejuvenation was a place where you could go and find that period fixture for the old house you were restoring,” Brandon says. “At some point, a switch happened. The brand went from being very period-authentic to having this great in-house design team where there’s a focus on taking inspiration from history and then designing new products across multiple aesthetics. I was drawn to that. I wanted to be a part of what was going on over there.” Since joining the company five years ago, Brandon has had his hands in countless new designs, working on as many as 10 collections at a time. The new Rigdon 10-Arm Chandelier is one of his latest.

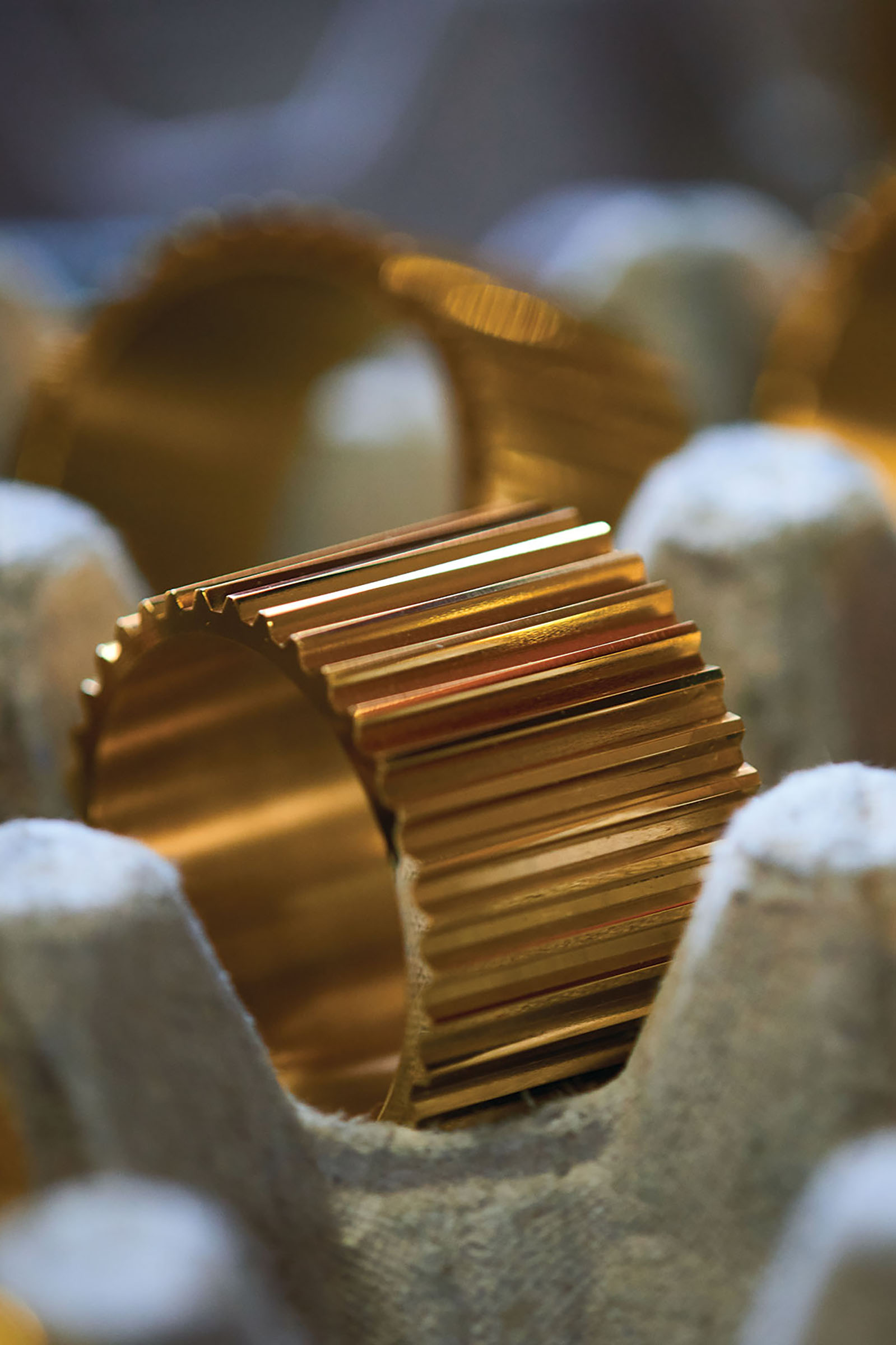

- Every day orders come in and employees pull the parts needed to make the fixture. Once picked, the brass parts move to the polishing wheel. Photo by Bill Whitmire

- In the polishing department, the brass pieces are polished to show off their sheen in a way you wouldn’t see with steel or aluminum. Photo by Bill Whitmire

- Most parts are solid brass. Each gets hand-polished on the polishing wheel before moving on to get its finish, which in this case is burnished antique. Photo by Bill Whitmire

- Parts go on a rack and are shot with a clear lacquer before going through the oven to be cured and sealed for protection. Photo by Bill Whitmire

Brandon says creating the 10-arm Rigdon was quite a process—he estimates it took 18 months at least. His process began in Rejuvenation’s in-house library, a painstakingly organized vault of catalogs, books, and artifacts going back to the 1800s. “There’s something about being in that physical space with all these old books and images. It’s more inspiring to me than flipping through images on a computer screen,” he says. An actual 1940s candlestick sitting in that library became the impetus for Rigdon, as Brandon picked it up and zeroed in on its coining detail and how it caught the light.

- In order to seal and protect the finish, the best tools are chosen from the paint and lacquer booth inside the Rejuvenation factory. Photo by Bill Whitmire

- In the hand burnishing department, steel wool is taken to each piece of the Rigdon to add highlights in the areas with coining details. Photo by Bill Whitmire

- The longer the parts stay in this bath the darker they get, revealing areas of the brass base layer below and giving the finish a warmth. Photo by Bill Whitmire

- You can customize the Rigdon 10-Arm Chandelier to meet your needs by choosing from nine finishes, two shades, and virtually any length. Photo by Bill Whitmire

On a typical day on the second floor above Rejuvenation’s retail space, Brandon and the five-person design team bounce ideas off each other, sketch, work in CAD, and venture over to the other side of the wall just footsteps away to talk through the design with the engineering team. “We go through rounds of sampling until we can land on the final design,” Brandon says. His favorite part, though, is the early stage—sketching, modeling, and seeing the piece come back as a sample for the first time. “It’s always really exciting to see something in front of you that you’ve been working on for so long.”

- The finished parts go to the assembly station in the warehouse, where they’re spread out and put together by Rejuvenation’s skilled craftspeople. Photo by Bill Whitmire

- A craftsperson wires the fixture and takes it to the electrical testing station, where it’s attached to a machine that uses a probe to touch the sockets. Photo by Bill Whitmire

- A coining detail from a 1940s candlestick inspired Rigdon. “It’s clean and cool, and it bounces the light around in an interesting way,” says Rejuvenation Lighting Designer Brandon Jorgensen. Photo by Bill Whitmire

- The design team was also inspired by the candlestick’s vertical lines. “The final execution highlighted our polished and burnished finishes.” Photo by Bill Whitmire

For the Rigdon, Brandon used a coining detail from the old candlestick at the center body of the chandelier and again at the end of the arm where the socket is. “I think we knew early on we had something here. We were excited,” he says. The team took that single chandelier into multiple sizes and then into the double arm seen today in the Rigdon 10-Arm. “That double-arm was the most challenging. From the factory side, it was challenging as far as assembly (it’s more than 400 pieces in total), and on the design side it’s got this inverted orientation of the arms; they’re intertwining, and that was an unexpected move,” Brandon says. “We started building it and we really liked the way the whole thing came together. That was probably the one piece in the whole extensive Rigdon collection (which includes sconces, a floor lamp, table lamp, desk, and more) that was unexpected and exciting at the same time.”

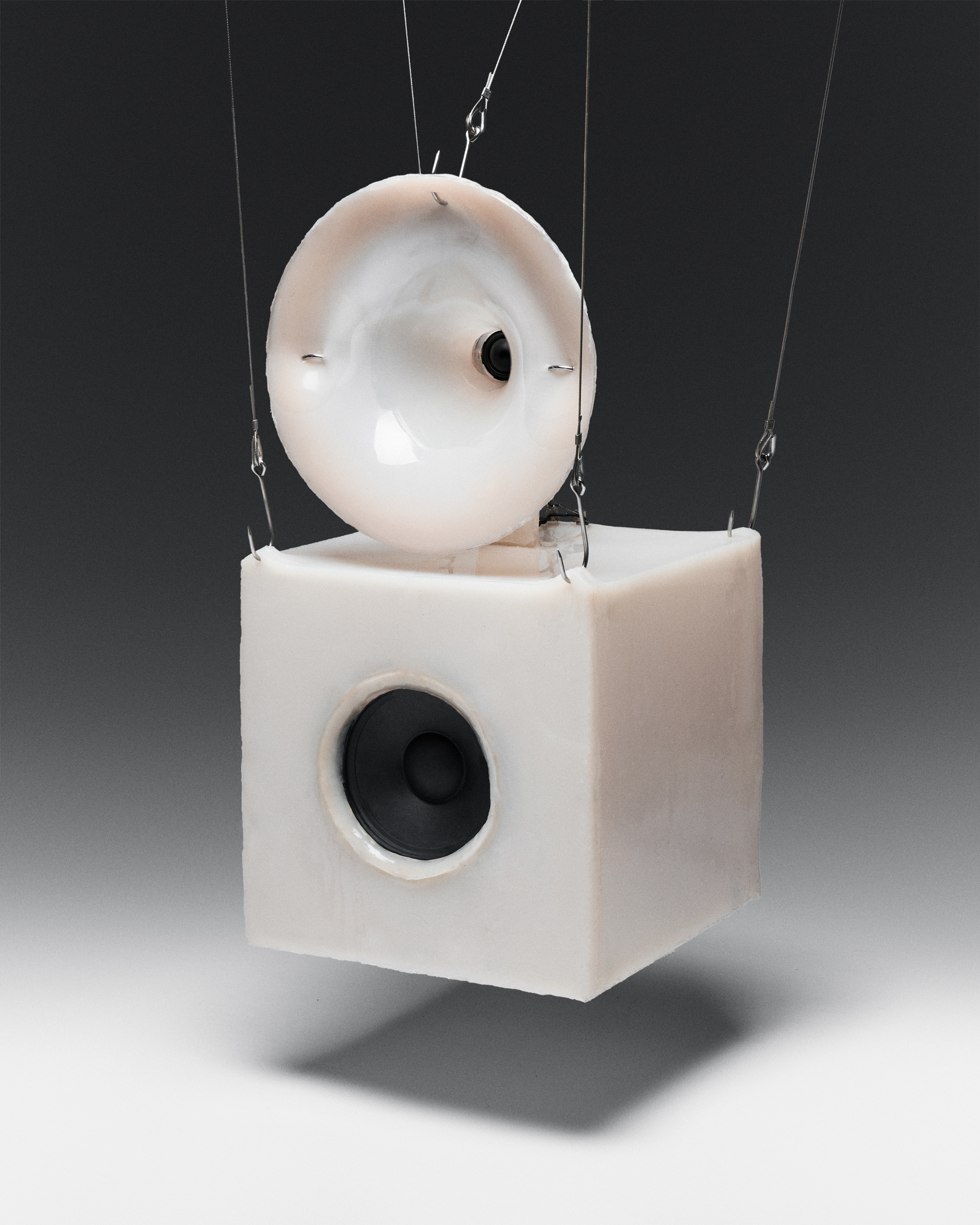

Brandon Jorgenson has been into design since he was a kid. “I wanted to be a cartoonist and then I realized I was more interested in how things are made and how they work. I’d take apart my Dad’s stereo, look at it to understand how it works, and then put it back together before he got home.” Photo by Bill Whitmire

This article originally appeared in the Spring/Summer 2020 issue of Sixtysix with the headline “Making the Rigdon Chandelier.” Subscribe today.

PRODUCTION CREDITS

Produced by Studio Sixtysix

Words by Laura Rote

Photos by Bill Whitmire

Studio Sixtysix is the in-house creative agency to Sixtysix magazine. Studio Sixtysix stories are conceived, produced, and edited by Studio Sixtysix.