Inga Sempé is a French product designer based in Paris, where she collaborates with two other designers. She has partnered with various Scandinavian, Italian, and French companies including HAY, Ligne Roset, Wästberg, and Alessi. In her work Inga focuses on creating sustainable, simple, yet not overly minimalist objects. She values functionality and the materials used, believing they should support the object’s purpose. Recently she developed Grotte, a prototype lamp in partnership with Hydro, constructed entirely from post-consumer scrap aluminum.

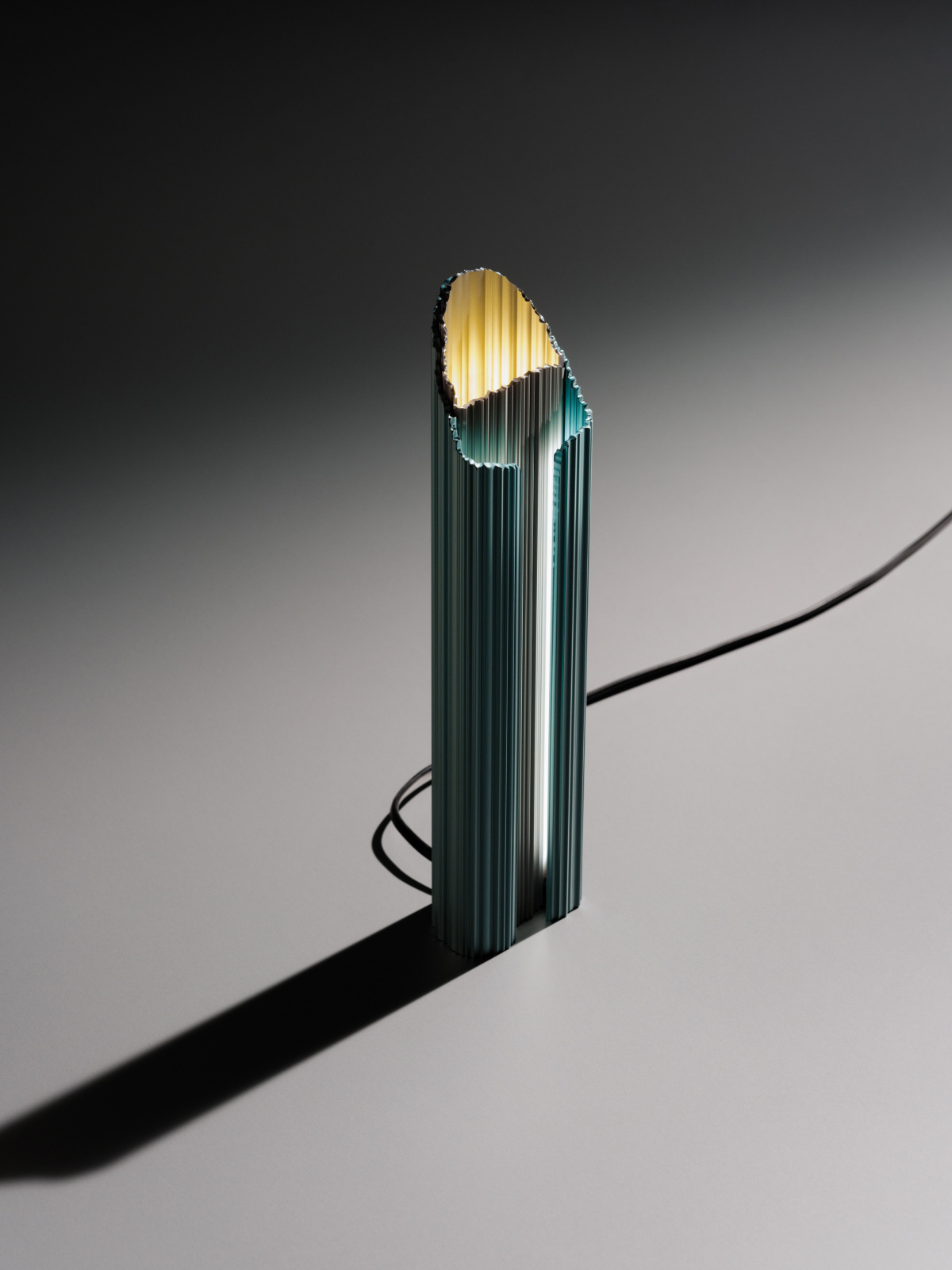

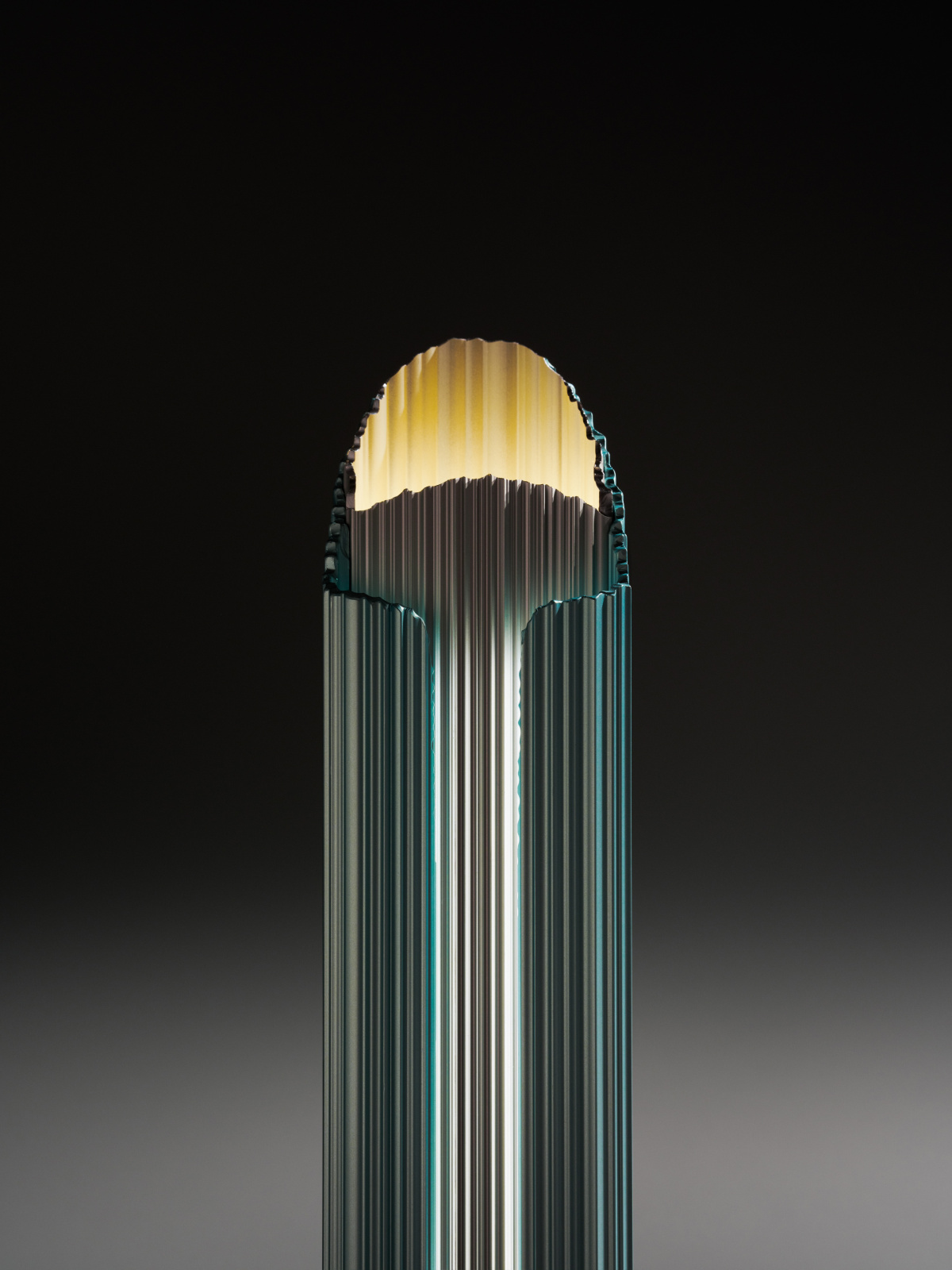

- Hydro, a Norwegian aluminium and renewable energy company, commissioned Inga and other designers to create the first industrial-scale aluminium material made from post-consumer scrap. Above, Inga’s piece, Grotte. Photo by Einar Aslaksen, courtesy of Hydro

- All creations were showcased at Milan Design Week in an exhibition titled 100R. Above, Inga’s piece, Grotte. Photo by Einar Aslaksen, courtesy of Hydro

Chris Force: How did this project come to be? Was there a brief for what they were looking to accomplish?

Inge Sempé: Our only direction was to use extrusion, try to learn about it a bit, and then do what we wanted.

Have you worked with extrusion before?

I haven’t, but it’s quite an easy technique and not too demanding from a financial point of view. I had to learn more about the way shapes should be made so there wouldn’t be deformation. Anything we didn’t know was explained to us by an engineer.

“If you have a full understanding you will shift the project,” Inga says. “If you don’t understand, it will shift you.” Photo by Chris Force

“Sometimes doing things that are painful help you realize you want another life because work is so important.”

The big talking point about this material is that it’s 100% post-consumer waste; it can be recycled an infinite number of times. How important is this material from Hydro?

I care about the material. To me it’s always interesting to meet with a company that has a very strong knowledge of materials because that’s what I’m interested in. The techniques are the most interesting and the most important to know. If you have a full understanding you will shift the project. If you don’t understand, it will shift you.

Have you ever said “no” to a project because the materials required weren’t being considered from a sustainability standpoint?

That’s a delicate subject because it’s hard to be a designer and to survive. It’s a very badly paid job. Sometimes you can’t say, “I won’t do that,” but I mostly work with high-quality companies. That protects me also from ending up with badly produced objects. We aren’t at the factory during production so we can’t check everything. As designers we don’t have that much power. Of course, if they say it’s a 100% recycled material, that’s great. But we don’t really know—we have to rely on trust. My personal trust comes from working with high-quality companies and familiar family companies for production.

We say we can do everything with wood, but then it’s a question of, which wood? Some woods you shouldn’t be cutting down anymore. It’s easy to say you’re designing very “cleanly.” It’s easy to look good. But it’s not easy to fully know what we’re using.

Through uniting with designers, Hydro shows how scrap can be turned into pristine looking design objects. Photo by Einar Aslaksen, courtesy of Hydro

How often do you see a product that doesn’t turn out how you expected?

There are so many designers working on a project, usually it happens between two to five years. We work for so long on each project that it doesn’t happen. We have many steps for production. It’s not as if we’re sending sketches to China and then it shows up in a container—at least not the companies I work with. Though sometimes it can happen if there is a problem finding a material. For example, the price of copper and brass has increased so much. The key is working for companies you can trust. You have to preserve the image of your brand.

Is there any material you haven’t worked in that you hope to in the future?

I had never worked with extrusions—that’s why I was really interested. I don’t use many materials I’ve never worked with. The important thing for me is working with companies that have the will to collaborate, who are interesting, and with whom you can have a dialogue. That ensures the product will be high quality.

Is there a type of company or project you would love to do?

I would like to design some pencils, some hand tools, and some gardening things that are interesting. I’m not sure what any of that would look like. I never have any ideas before working on a project. Even when I begin to work on a project, for a long time I don’t have any idea.

How do you start then? What’s your typical first step?

Typically sketches. It depends. Now I use my iPad when designing fabrics. For certain projects I prefer to create it on my iPad because it’s easy to enlarge and design thread by thread. I would never be able to do that by hand.

Hydro’s exhibition 100R at Milan Design Week. Designers have a powerful role to play in accelerating the green transition, as up to 80 percent of a product’s environmental impact is decided at the drawing board. Photo by Einar Aslaksen, courtesy of Hydro

In your career has there ever been a big mistake or turn you wish you hadn’t made?

I should have begun earlier, but in the past I was afraid. I didn’t feel comfortable enough to collaborate with people. I wasn’t daring enough because I’m very lazy. After doing some bad jobs and working for other designers for awhile, which I hated, I decided to make a change. Sometimes doing things that are painful help you realize you want another life because work is so important.

When young people are asking you for advice, what do you normally tell them?

They don’t need to be trustful in themselves. They should not have self-confidence. I think it’s ridiculous to tell young people they should be self-confident. Some self-confident young designers end up producing things that are very bad. The only thing to be sure of is if you want to be part of the design space—and for what reasons. Is it because you want to be in a magazine? If so you might want to do another job. Is it because you want to go to factories, meet some people, understand techniques and the needs of a company? Do you want to create long lasting products? Then yes, do it.

A version of this article originally appeared in Sixtysix Issue 12.