Good furniture often references architecture without mimicking it. Brooklyn-based designer Ford Bostwick’s Domino Side Table takes this seriously, distilling one of modernism’s most foundational architectural ideas into something you can set a book on.

Domino draws from Le Corbusier’s 1914 Dom-Ino House, a housing prototype that was never built but became more influential than most constructed buildings. Le Corbusier sketched it during WWI as affordable housing for Belgian refugees whose towns had been destroyed. His idea was simple: concrete floors held up by skinny columns at the edges. No walls did any heavy lifting or fixed a room’s layout, but instead acted as a bare skeleton that people could fill in however they wanted.

Domino draws from Le Corbusier’s 1914 Dom-Ino House, a housing prototype that was never built but became more influential than most constructed buildings. Photo courtesy of Ford Bostwick

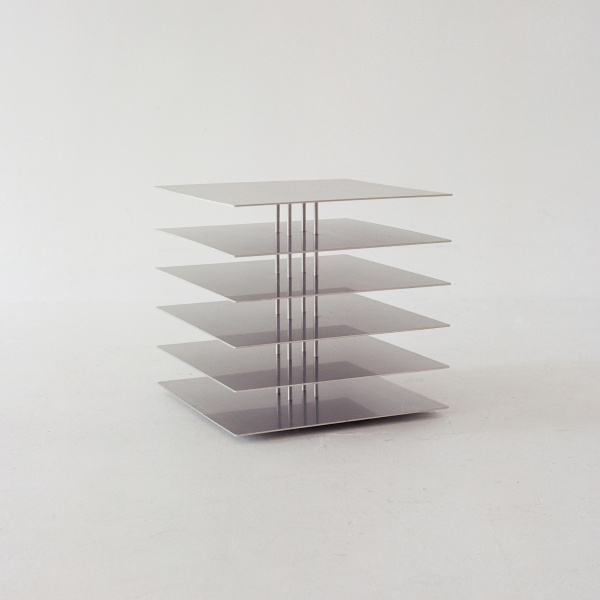

Ford took that idea and rebuilt it as a stainless steel side table. Flat metal plates stack at different heights connected by thin vertical posts. Depending on the angle, a trick of the eye makes those posts seem to vanish. Suddenly you’re staring at shelves floating in space with no visible means of support.

“I was also influenced by seeing buildings wrapped in scaffolding and debris netting, where in certain light even very monolithic structures can seem to dissolve,” Ford says. The welding and all the hardware are completely hidden using a low-heat welding technique (which is necessary, because stainless steel warps like crazy if you’re not careful).

While the table looks delicate, it weighs over 50 pounds. Every piece is laser-cut from a steel plate, then sanded and assembled by hand in New York. Local production means Ford can tweak sizes and offer powder-coated finishes if you want color instead of raw steel.

While the table looks delicate, it weighs over 50 pounds. Every piece is laser-cut from a steel plate, then sanded and assembled by hand in New York. Photo courtesy of Ford Bostwick

Ford’s design process is methodical. “I usually have a clear idea before I start making anything, and the first prototype tends to be about 90% there,” he says. “The last 10%—small changes to proportions, hardware, or removing unnecessary details—often take the most time.” For this table, that final 10% meant five more rounds of revisions over a year, tweaking everything until the optical trick worked from every angle.

The table really comes alive when you can circle it and watch the posts appear and disappear. Ford envisions it working alongside contemporary pieces or as a quiet counterpoint in traditional interiors.

Made to order in New York, each table costs $3,200 and takes six to eight weeks to fabricate. You can grab one at Love House in New York, Adorno Design, or directly through Ford’s studio, fordbostwick.com.